Good Solar Production is about Current Flow

Believe it or not, the easy part is converting sunlight into electrical current; the hard part is making sure the current flow is unimpeded. Once we have achieved sunlight to electric energy conversion, there are many ways in which current can be restricted, diminished or interrupted. This article is about what we do to prevent this from happening.

The first and most common obstacle to current is soiling on the PV module glass. This is also the easiest one to prevent or correct by simply cleaning it. Cleaning the glass also prevents long-term damage to the PV cells.

The second potential obstacle is an electrical connector. These include the polarized PV connectors and every other connection where one conductor is connected to another. This is the most common failure point on a PV system and it is a potential fire hazard as well. The connection must be made as perfect as possible and it must be rated for the maximum voltage, current and temperature of the circuit.

- This is can be a failure point of both voltage and current. Follow the connector installation instructions and practice making them to perfection. Inspect them regularly for visual deformation and for excessive heat with an IR scan.

The third potential obstacle to current flow is the electrical conductor. These vary in size and insulation coverings depending on the voltage, current, temperature rating and environment in which the conductor will be placed. The current rating is primarily determined by the size of the conductor but the conductor insulation has an effect on the current rating as well. The insulation also determines the voltage, temperature and environment rating of the conductor.

- In short, we are looking at the conductor size and its insulation covering when selecting the correct conductor. This requires some knowledge of NEC tables.

NEC tables in Chapter 3 and 4 identify conductor insulation coverings so we can select the correct conductor for the application.

- Table 310.4(1) is commonly used for conductors rated to 600v.

The next tables are based on the max-circuit-current. This is calculated by taking the listed max current of the device and multiplying it by 125%. [e.g. max current 15 amps x 125% = 18.75 amps]

The conductors, connections and overcurrent devices must be rated no less than this calculated circuit rating.

- PV wire is run in open air so the #12 module conductors are rated at least 35 amps and the PV wire installed by the contractor is #10 and rated no less than 55 amps. This is more than sufficient in any open-air condition.

- Table 310.16 lists the ampacities of conductors in conduit; these are conductors other than PV wire. Go the 90°C column and drop down until you see an ampacity that is greater than the calculated circuit ampacity requirement and you have found your conductor size and the conductor’s ampacity rating.

Unfortunately, there are two factors that can reduce the ampacity of the conductor: Temperatures above 30°C and more than 3-conductors in the conduit.

- Table 310.15.(B)(1) provides the percentage of ampacity loss for temperatures over 30°C.

- Table 310.15(C)(1) provides the percentage of ampacity loss for more than 3-conductors run in a conduit.

Once the selected conductor ampacity has been reduced with these loss factors, it’s ampacity must still be greater than the max current rating of the devices in the circuit; if less, a larger size conductor must be selected.

For a more in-depth review of conductor selection, take our PV221-70(A) PV Circuit Conductor Requirements course.

If you are new to solar, take our PV201OL PV Design and Installation course first and then take PV221-70(A).

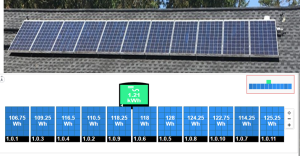

The fourth potential obstacle to current flow is damage to the PV cells within the PV module. There are numerous conditions that can cause a reduction in current output such as PV cell hot spots, micro-cracks, light induced degradation (LID), potential induced degradation (PID) as well as delamination, burned solder joints and failing bypass diodes.

- Identifying them requires tools such as IR cameras and a good understanding of the PV module failure modes.

Our PV223 PV System Maintenance and Troubleshooting course covers these conditions in depth.

Kelly Provence

IREC Certified Master PV Trainer

Solairgen School of Solar Technology

www.solairgen.com